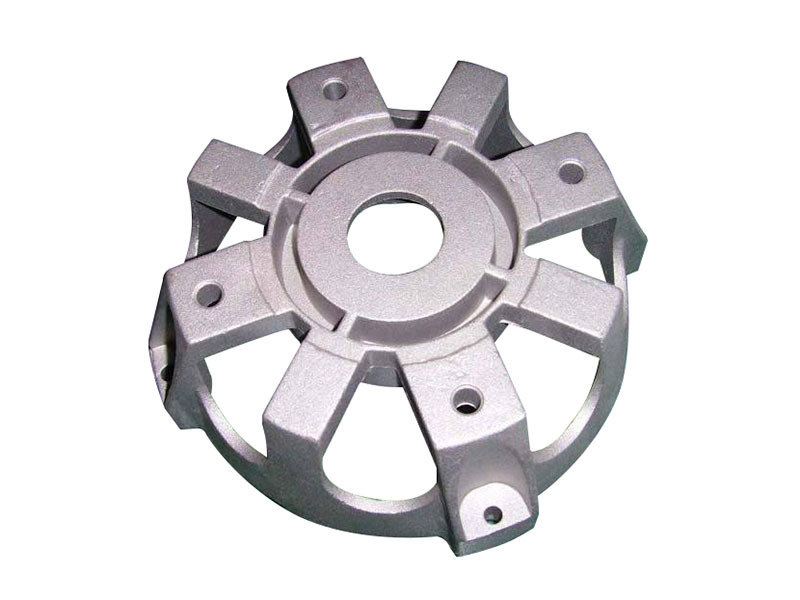

Processing steps of aluminum alloy casting parts

Release time:

2022-07-22

Due to the different shapes of aluminum alloy castings, different cleaning methods are required. The flexible shaft is cleaned in the casting pipe hole by rotating equipment, which is suitable for occasions where important castings cannot be heated by vibration. Next, we will look at the processing methods of aluminum alloy castings. And cleaning methods. The processing steps of aluminum alloy casting parts:(1) the aluminum alloy casting parts after solution treatment are heated to a set temperature and come out after a period of time. The method of slowly cooling in the air is called aging. Aging strengthening is completed at room temperature. Natural aging is completed at room temperature, while aging strengthening is completed after artificial aging after holding for a period of time in an environment higher than room temperature. Aging causes supersaturation

Duealuminum alloy castingDifferent shapes require different cleaning methods. The flexible shaft is cleaned in the cast pipe hole by rotating equipment. It is suitable for occasions where important castings cannot be heated by vibration. Let's take a look nextaluminum alloy castingprocessing methods and cleaning methods.

aluminum alloy castingProcessing steps of parts

(1) After solution treatmentaluminum alloy castingThe method of slowly cooling in air after heating to a set temperature is called aging. Aging strengthening is completed by natural aging at room temperature, while aging strengthening is completed by artificial aging after holding for a period of time in an environment higher than room temperature. The spontaneous process of decomposition of supersaturated solid solution caused by aging can make the lattice of alloy matrix return to a relatively stable state.

(2)aluminum alloy castingUsually heatedAbout 300, after holding for a period of time, the process of cooling to room temperature in the furnace is called annealing. When annealing, the solid solution decomposes and the second phase particles aggregate, which can eliminate the internal stress of the casting, stabilize the size of the casting, avoid deformation and improve the plasticity of the casting.

(3) willaluminum alloy castingThe workpiece is heated to the melting point of eutectic, kept at this temperature for a long time, and then rapidly cooled to make the strengthening components dissolve well. This high temperature state is kept at room temperature. This process is called solid solution treatment. Solid solution treatment can improve the strength and plasticity of the casting and the corrosion resistance of the alloy. The effect of solid solution treatment is usually related to the solid solution treatment temperature, solid solution treatment holding time and cooling speed.

aluminum alloy castingCleaning method

1.aluminum alloy castingSand blasting.

2. Mechanical sand cleaning treatment.

3. Compressed air cleaning.

4. Casting aluminum parts with liquid sandblasting machine sandblasting.

5. Cast aluminum with pneumatic pick to clean sand, cast aluminum with fragile resin heating after slight vibration core, when buried copper pipe instead of sand core cast pipe cleaning, can be 40-50% nitric acid soak to remove.

Gravityaluminum alloy castingWhat are the advantagesWhat?

For aluminum alloy, if the crystallization temperature range is wide, the probability of mesh pinhole is much greater, because under the general casting production conditions, the solidification temperature range of die-cast aluminum is wide, and it is easier to make aluminum alloy form developed dendrites, thenGravity aluminum alloy castingWhat are the advantages?

1. The thermal conductivity and heat capacity of the metal profile are large, the cooling speed is fast, the casting organization is dense, and the mechanical properties are about 15% higher than the sand mold.

2、Aluminum alloy casting can beIn order to obtain high dimensional accuracy, low surface roughness of the casting, stable quality, long service life.

3, do not need or rarely use sand core, can improve the environment, reduce dust and harmful gases, reduce labor intensity.

4,aluminum alloy castingSimple process, reduce mechanical processing, employee safety and environmental protection.

5,Canto produce products of greater thickness.

6、aluminum alloy casting productsCan be heat treated.

Key words:

Next Page

Recommended News

What is the aluminum alloy casting process?

2022-08-31

How to Avoid Aluminum Alloy Casting Error

2022-08-22

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.