Advantages of low pressure casting

Release time:

2020-11-23

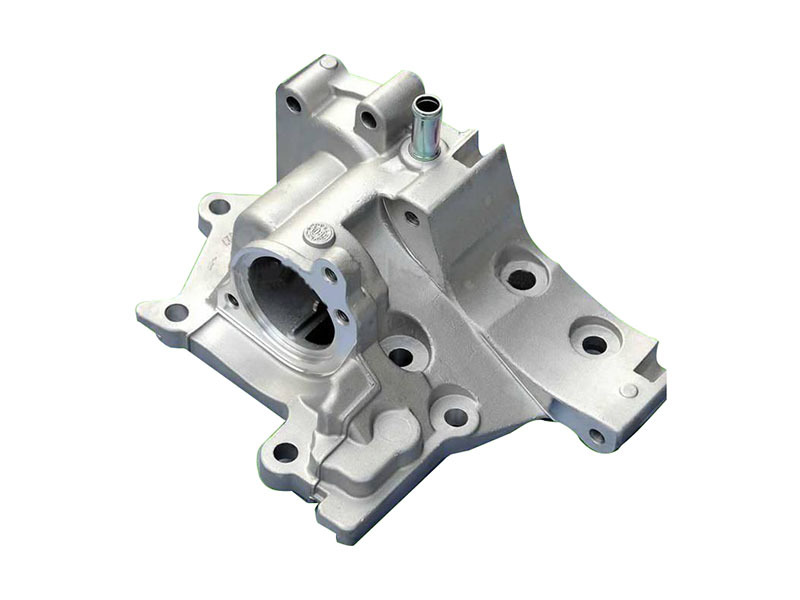

Low-pressure casting is an earlier counter-gravity casting technique used in industrial production in the 1940 s. Nowadays, low-pressure casting is mainly used to produce aluminum alloy and magnesium alloy parts, such as automobile wheels, cylinder blocks, cylinder heads, pistons, impellers, wind guides and other castings with complex shapes in the automotive industry.

Low pressure casting is an earlier anti-gravity casting technology, inUsed in industrial production in the 1940 s. Nowadays, low-pressure casting is mainly used to produce aluminum alloy and magnesium alloy parts, such as automobile wheels, cylinder blocks, cylinder heads, pistons, impellers, wind guides and other castings with complex shapes in the automotive industry.

The automotive industry has high quality requirements. When using low-pressure casting to produce cast steel, the riser must be made of special refractory materials. Low pressure casting can also be used for small copper alloy castings, such as pipe fittings, cock faucets in bathrooms, etc. The technology has been industrialized abroad.

Low pressure casting can use sand, metal, graphite, etc. The filling process is different from gravity casting (such as metal casting and sand casting), and also different from high-pressure and high-speed filling pressure casting. Has the following advantages:

1,Filling with pure liquid metal increases the purity of the casting. Since the molten slag usually floats on the surface of the molten metal, the low-pressure casting fills the molten metal at the lower part of the crucible through the riser, thereby avoiding the possibility of molten slag entering the cavity.

2、The molten metal is evenly filled, reducing or avoiding the rolling, impact and splashing of the molten metal during the filling process, thereby reducing the formation of oxide slag.

3,Good formability of low pressure casting. The molten metal is filled under pressure, which can improve the fluidity of the molten metal, which is conducive to the formation of castings with clear contours and smooth surfaces, and is more conducive to the formation of large thin-walled castings.

4,The casting crystallizes and solidifies under pressure, can be fully fed and the casting structure is dense.

5,Low pressure casting can improve the yield of molten metal. Under normal circumstances, no riser is required, and the uncondensed metal in the riser can be refluxed into the crucible for reuse, which greatly improves the yield of molten metal. Usually up90%

6、Convenient production and operation, good working conditions, high production efficiency, easy to realize mechanization and automation,

Low pressure casting also has some disadvantages. The investment in equipment and molds is relatively large. In the production of aluminum alloy castings, the crucible tube and the riser are in contact with the molten metal for a long time and are susceptible to corrosion and debris, which will also cause the molten metal to increase iron and reduce its performance.

Key words:

Previous Page

Previous Page:

Next page:

Recommended News

What is the aluminum alloy casting process?

2022-08-31

How to Avoid Aluminum Alloy Casting Error

2022-08-22

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.