Cast aluminum manufacturers: the characteristics of aluminum castings and cleaning methods

Release time:

2021-02-04

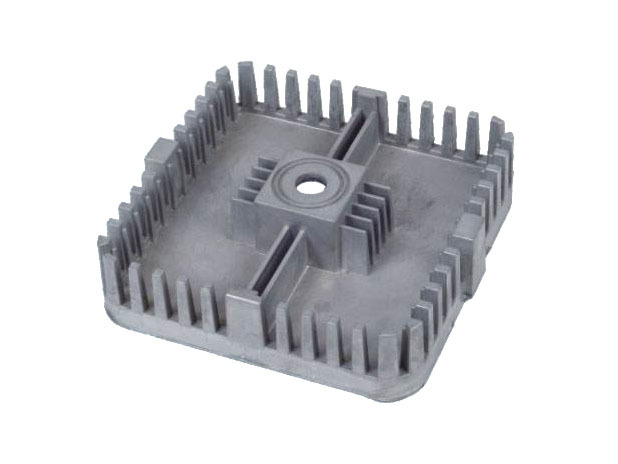

Aluminum castings come in a wide range of weights and sizes. The lighter weight is only a few grams, the heavier is 400 tons, the thinner wall thickness is only 0.5mm, the thicker is more than 1 meter, and the length ranges from a few millimeters to more than ten meters. It can meet the requirements of different industries. Generally, for the appearance quality of aluminum castings, aluminum casting manufacturers can judge the surface roughness of aluminum castings by comparing samples, and can check the fine cracks on the surface by coloring and magnetic particle method. The internal quality of aluminum castings can be inspected and judged by audio, ultrasonic, eddy current, X-ray and gamma ray.

Aluminum castings come in a wide range of weights and sizes. The lighter ones weigh only a few grams, and the heavier ones are400 tons, the thinner wall thickness is only 0.5mm, the thicker is more than 1 meter, and the length ranges from a few millimeters to more than ten meters. It can meet the requirements of different industries. Generally, for the appearance quality of aluminum castings, aluminum casting manufacturers can judge the surface roughness of aluminum castings by comparing samples, and can check the fine cracks on the surface by coloring and magnetic particle method. The internal quality of aluminum castings can be inspected and judged by audio, ultrasonic, eddy current, X-ray and gamma ray.

The quality of aluminum castings manufactured by aluminum casting manufacturers has a great influence on the performance of mechanical products. For example, the size of the impeller, the size of the housing and cavity, the surface accuracy and surface roughness of various pumps directly affect the working efficiency, energy consumption and cavitation development of the pump and hydraulic system. The strength and cold resistance of cast aluminum parts such as cylinder blocks, cylinder heads, cylinder liners, piston rings, and exhaust pipes of internal combustion engines directly affect the service life of the engine.

The selection principle of aluminum casting casting method: sand casting is better for casting aluminum castings, mainly because sand casting is cheaper than other casting methods, the production process is simpler, and the production cycle is shorter. When the wet mold can not meet the requirements, cast aluminum manufacturers will consider the use of clay sand surface dry sand mold, dry sand mold or other sand mold. The casting method for aluminium castings shall be suitable for the production batch. Due to the high price of equipment and molds, low-pressure casting, die casting, centrifugal casting and other casting methods are only suitable for mass production. Aluminum castings manufactured by aluminum manufacturers can be single-piece castings or mass production.

The shrinkage porosity of aluminum castings usually occurs at the transition of the thicker part of the riser root near the inner runner, the wall thickness and the thin wall with a larger plane. Cast aluminum manufacturers found that the cast cracks are gray, light yellow, light yellow or gray black after heat treatment.

Key words:

Previous Page

Recommended News

What is the aluminum alloy casting process?

2022-08-31

How to Avoid Aluminum Alloy Casting Error

2022-08-22

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.