Aluminum casting plant: what are the surface treatment methods of aluminum casting

Release time:

2021-04-13

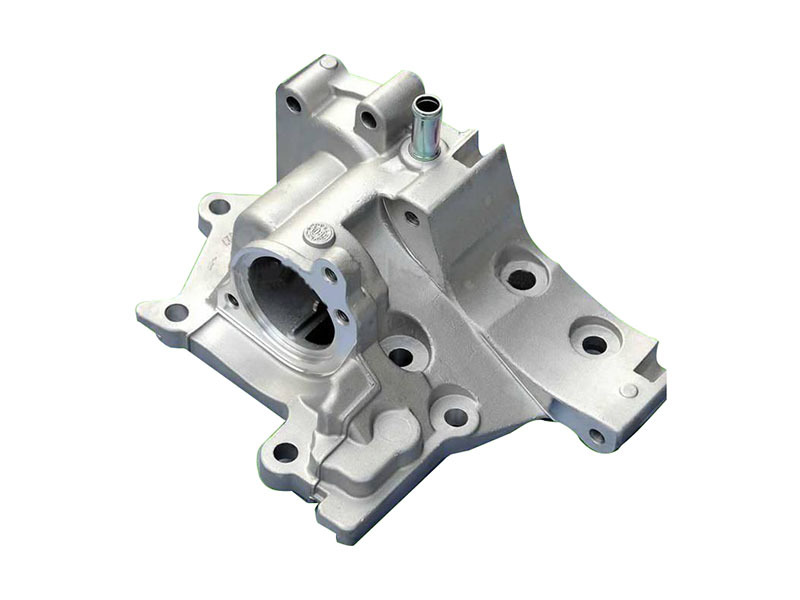

Aluminum casting is a common processing method in aluminum processing, and it is also a common processing method in aluminum processing. Since aluminum itself is a metal with poor stability and quality, aluminum casting plants usually need to treat the surface of aluminum die castings after aluminum casting. According to the actual use of different processing methods. Here for everyone to briefly introduce.

Aluminum casting is an aluminum casting plantInThe more commonly used processing methods in aluminum processing are also common processing methods in aluminum processing. Since aluminum itself is a metal with poor stability and quality, aluminum casting plants usually need to treat the surface of aluminum die castings after aluminum casting. According to the actual use of different processing methods.Here for everyone to briefly introduce.

1. Oxidation treatment: The surface of aluminum alloy is oxidized, suitable for conductive oxidation, and aluminum or aluminum profiles are suitable for anodizing.

2. Sandblasting: The aluminum casting factory sprays a layer of fine sand on the surface of the aluminum casting product to increase the friction coefficient of the contact surface, thereby improving the reliability of the connection. The sand has different thicknesses and textures.

3. Electroplating treatment: Electroplating is the process of depositing metal or alloy on the surface of the workpiece through electrolysis to form a uniform, dense and well-bonded metal layer, called electroplating. A simple understanding is a change or combination of physics and chemistry.

4. Powder spraying (ie powder spraying): Powder spraying is the use of powder spraying equipment in aluminum casting plants to spray powder coating on the surface of aluminum casting workpieces. Under the action of static electricity, the powder will be evenly absorbed on the surface of the workpiece to form a powder coating. After high temperature baking, leveling and curing, the powder coating becomes a coating with different powder coating effects. In terms of mechanical strength, adhesion, corrosion resistance and aging resistance, the spraying effect of powder spraying is better than that of spraying process.

5. Baking paint treatment: The baking paint process is the aluminum casting plant uses aluminum alloy for phosphating treatment and spraying, and then in the aluminum castingOn the workpieceBake after spraying. Such a coating is not only corrosion-resistant, but also bright and wear-resistant, and does not easily fall off.

The above is aluminum casting factoryRight.aluminum castingWorkpieceIntroduction of several surface treatment methods. In the actual industrial production, it is often necessary to choose the appropriate processing method according to the actual situation and the actual use of the corresponding aluminum die castings.neededeffect and economy.

Key words:

Recommended News

What is the aluminum alloy casting process?

2022-08-31

How to Avoid Aluminum Alloy Casting Error

2022-08-22

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.