A brief introduction to the casting mold

Release time:

2021-06-17

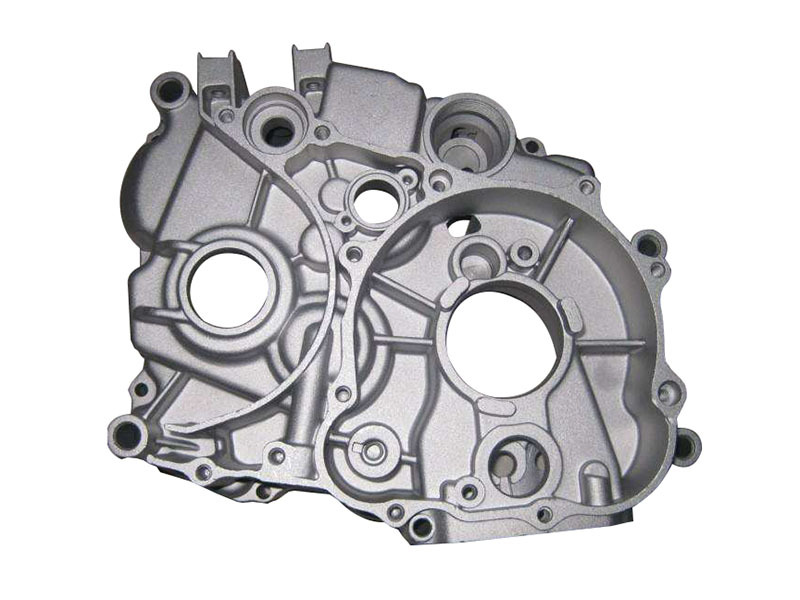

Casting mold refers to the structural shape of the parts in order to obtain the structural shape of the parts, using other easy-to-form materials to make the structural shape of the parts in advance, and then put the mold into the sand mold, so that the cavity parts with the same structure are molded in the sand mold. The fluid liquid is then poured into the cavity. After the liquid is cooled and solidified, parts with the same shape and structure as the mold can be formed. The casting mold is an important part of the casting process.

casting mouldRefers to the structural shape of the part in order to obtain the structural shape of the part, the structural shape of the part is made in advance with other easy-to-form materials, and then the mold is placed in the sand mold, so that the cavity parts with the same structure are molded in the sand mold. The fluid liquid is then poured into the cavity. After the liquid is cooled and solidified, parts with the same shape and structure as the mold can be formed.casting mouldIt is an important part of the casting process.

casting mouldRefers to the mold used to shape the casting in the casting process. Casting molds are matched with the casting process, mainly gravity casting molds, high-pressure casting molds (pressure.casting mouldtools), low-pressure casting molds, squeeze casting molds, etc., casting molds are one of the important process equipment..In the production of castings, this has a great influence on the quality of castings. The improvement of mold technology is of great significance for improving the quality of castings, developing new castings and improving the level of near-net processing.casting mouldThe progress of technology will provide more precise, complex and high-quality castings for automobile, electric power, ship, rail transit, aerospace and other industries, and promote the improvement of the overall level of manufacturing industry.

With the rapid development of automobile, motorcycle, aerospace and other industries, casting molds are increasing every year.More than 25% of the rapid growth rate. Casting mold technology has made great progress, but the automobile as the representative of the large aluminum alloy engine block, complex pressurecasting mouldIt is mainly dependent on imports. China's automobile and motorcycle industry has entered a period of rapid growth, and its output has increased significantly for many years. It is foreseeable that the future10 to 20 yearscasting mouldProduction will continue to be driven by strong thrust and rapid growth, mainly from the automotive industry. In the context of energy saving and emission reduction, the growth of ferrous metal gravity casting molds will slow down, while the aluminum-magnesium alloy pressure will slow down.CastCasting molds, low-pressure casting molds and squeeze casting molds will increase significantly.

Key words:

Previous Page

Recommended News

What is the aluminum alloy casting process?

2022-08-31

How to Avoid Aluminum Alloy Casting Error

2022-08-22

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.