A simple understanding of aluminum alloy casting

Release time:

2021-08-09

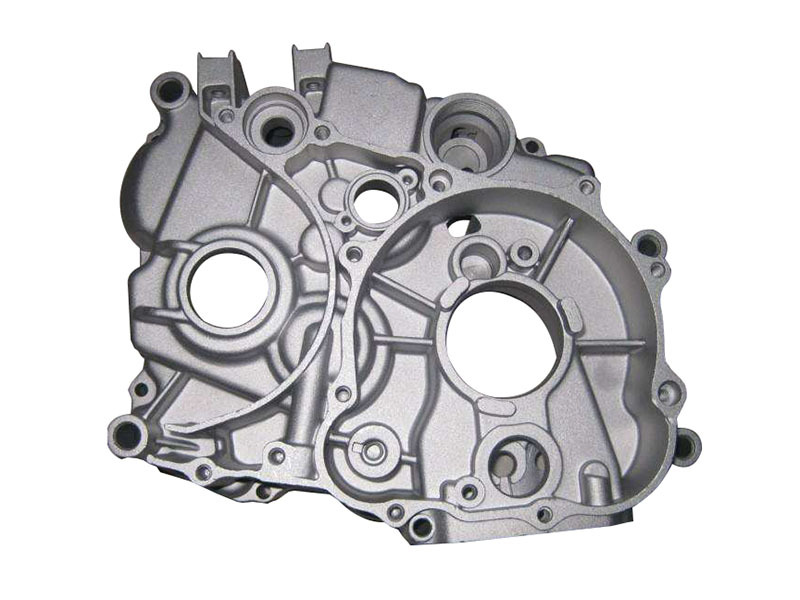

Aluminum alloy casting is to fill molten metal in a mold to obtain aluminum alloys of various shapes of parts. It has the advantages of low density, high specific strength, good corrosion resistance and casting processability, and less restrictions on part structure design. Aluminum alloy casting can be divided into Al-Si and Al-Si-Mg-Cu-based medium-strength alloys, aluminum-copper-based high-strength alloys, aluminum-magnesium-based corrosion-resistant alloys, and Al-Re-based hot-strong alloys. Most of the heat treatment is required to achieve the purpose of strengthening the alloy, eliminating the internal stress of the casting, and stabilizing the organization and size of the parts. Aluminum alloy casting is generally used in the manufacture of beams, gas turbine blades, pump bodies, pylon, hub,

Aluminum alloy casting is to fill molten metal in a mold to obtain aluminum alloys of various shapes of parts. It has the advantages of low density, high specific strength, good corrosion resistance and casting processability, and less restrictions on part structure design. Aluminum alloy casting can be dividedAl-Si and Al-Si-Mg-Cu-based medium-strength alloys; aluminum-copper-based high-strength alloys; aluminum-magnesium-based corrosion-resistant alloys; Al-Re-based hot-strength alloys. Most of the heat treatment is required to achieve the purpose of strengthening the alloy, eliminating the internal stress of the casting, and stabilizing the organization and size of the parts. Aluminum alloy casting is generally used to manufacture beams, gas turbine blades, pump bodies, hangers, hubs, intake lips and engine shells. It is also used in the manufacture of automobile cylinder heads, gearboxes and pistons, instrument housings and turbocharger pump bodies.

Aluminum alloy casting has good casting performance and can be made into parts with complex shapes; it does not require a lot of additional equipment; it has the advantages of saving metal, reducing costs, and reducing working hours, and is widely used in aviation, civil and other industries. Aluminum alloy casting is used to manufacture beams, gas turbine blades, pump bodies, towers, hubs, intake lips and engine casings. It is also used in the manufacture of automobile cylinder heads, gearboxes and pistons, instrument housings and turbocharger pump bodies.

Aluminum alloy casting is mainly to remove gas and non-metallic inclusions in the alloy liquid. The gas in the aluminum alloy is mainly hydrogen (accountingMore than 85%), inclusions are mainly alumina. Since the saturation solubility of hydrogen in liquid and solid aluminum alloys is nearly 20 times different, hydrogen is easily precipitated during the solidification process of aluminum alloy casting, resulting in pinholes in castings. Inclusion and gas interaction.

When industrial pure aluminumWhen the hydrogen content in 100 grams of aluminum alloy liquid is higher than 0.1 milliliters, pores will appear, while in high-purity aluminum, every 100 grams of aluminum alloy liquid contains hydrogen. When the volume of aluminum alloy casting is as high as 0.4 ml, pores will appear. It can be seen that degassing requires slag removal, and slag removal is the basis of degassing.

Key words:

Recommended News

What is the aluminum alloy casting process?

2022-08-31

How to Avoid Aluminum Alloy Casting Error

2022-08-22

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.