A brief understanding of the casting process of aluminum casting

Release time:

2021-11-17

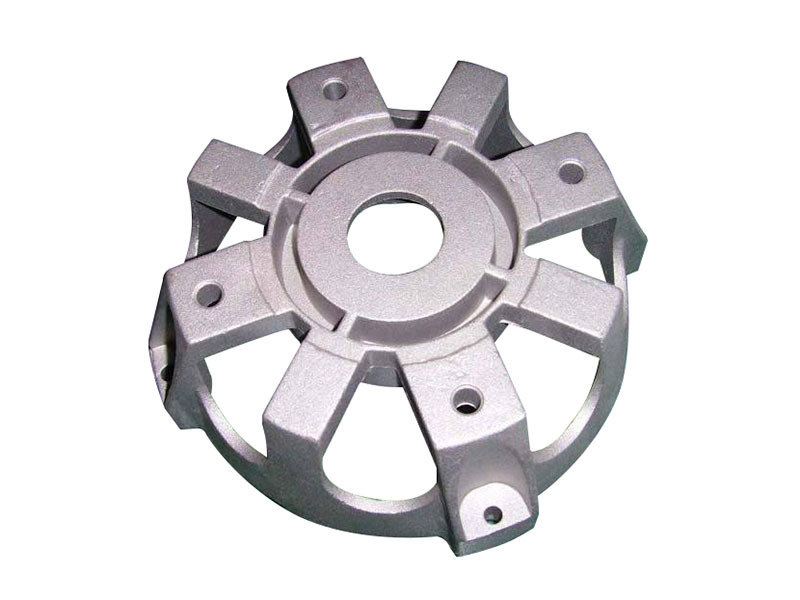

The aluminum casting process generally melts aluminum directly, and then puts it into the mold for operation to make the shape of the product that the customer wants. It can be said that the use of a wide range, such as machine tools, cars, tractors and many other places. You will use it, but what are the main types of aluminum casting products? How many casting processes can aluminum casting be divided. The main process of aluminum casting includes: metal smelting, model manufacturing, pouring solidification, demoulding and cleaning. The main materials used in casting are cast steel, cast iron and cast non-ferrous alloys (copper, aluminum, zinc, lead, etc.). Aluminum casting process can be divided into sand mold

The aluminum casting process generally melts aluminum directly, and then puts it into the mold for operation to make the shape of the product that the customer wants. It can be said that the use of a wide range, such as machine tools, cars, tractors and many other places. You will use it, but what are the main types of aluminum casting productsWhat?How many casting processes can be divided into aluminum casting?Just come.A brief introduction to aluminum castingProcessThe main types.

The main process of aluminum casting includes: metal smelting, model manufacturing, pouring solidification, demoulding and cleaning. The main materials used in casting are cast steel, cast iron and cast non-ferrous alloys (copper, aluminum, zinc, lead, etc.).

Aluminum casting process can be divided into sand casting process and special casting process. When pressing the investment mold, the pressure type with high cavity surface finish is used, so the surface finish of the investment mold is also relatively high. In addition, the shell uses a special high-temperature adhesive and a refractory coating made of refractory materials, which is coated on the investment mold. The inner surface of the cavity that is in direct contact with the molten metal has a high-finish refractory coating. Therefore, the surface finish of aluminum castings is higher than that of ordinary castings.

A major advantage of using aluminum castings is the high dimensional accuracy and surface finish of the investment castings. During the operation, the processing workload can be reduced, but the machining allowance for parts with higher requirements is smaller. However, even some castings have only a grinding allowance and can be used without machining. Visible, investment casting method can save a lot of machine tools and processing man-hours, greatly saving metal raw materials.

After introducing the above content, do you know more about aluminum casting? If you need to buy aluminum casting products, you can call us to buy them.

Key words:

Previous Page:

Recommended News

What is the aluminum alloy casting process?

2022-08-31

How to Avoid Aluminum Alloy Casting Error

2022-08-22

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.