Aluminum casting manufacturers: the main advantages of aluminum casting

Release time:

2020-12-07

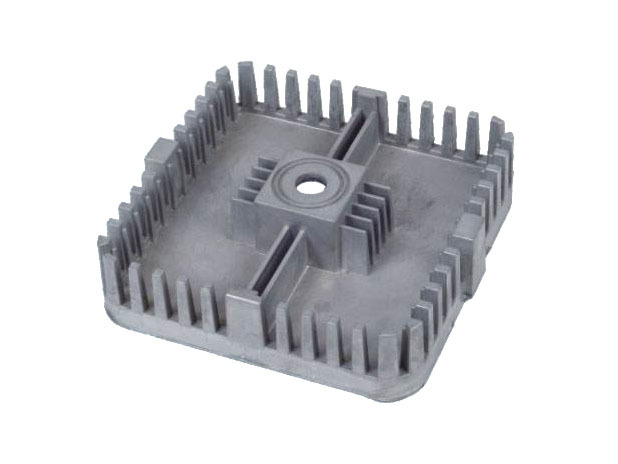

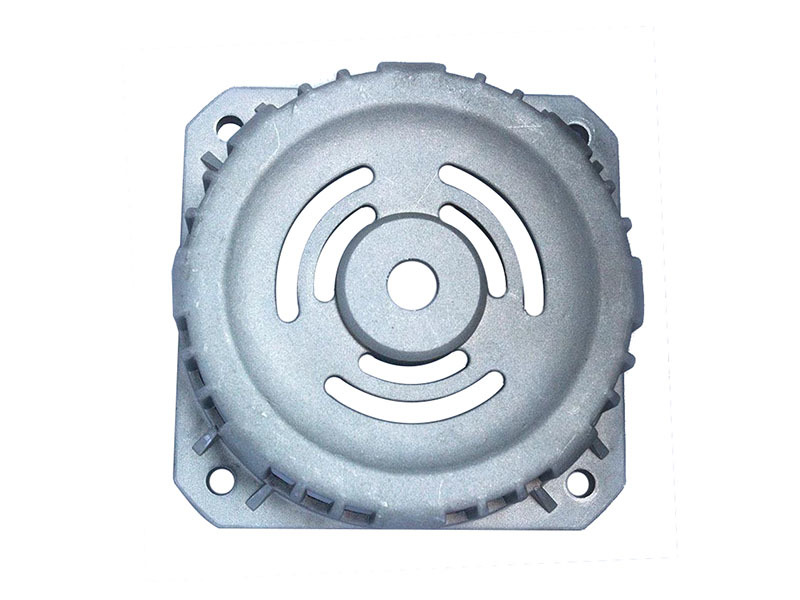

Aluminum casting manufacturers in the actual operation of casting aluminum alloy castings in the whole process will have other casting unparalleled advantages, especially in the automotive new energy so far, its casting aluminum alloy profiles in the car industry production has been widely used. Subsequently, the aluminum alloy profile sand casting process has excellent casting effect. Due to the low melting point, aluminum foundry manufacturers can generally adopt casting methods such as metal material type and working pressure casting to develop the inner letter quality of castings, limit precision and smooth surface level and its production output power.

Aluminum casting manufacturers in the actual operation of casting aluminum alloy castings in the whole process will have other casting unparalleled advantages, especially in the automotive new energy so far, its casting aluminum alloy profiles in the car industry production has been widely used. Subsequently, the aluminum alloy profile sand casting process has a good role. Due to the low melting point, aluminum foundry manufacturers can generally adopt casting methods such as metal material type and working pressure casting to develop the inner letter quality of castings, limit precision and smooth surface level and its production output power.

The density of foundry when casting aluminum alloy castings by aluminum foundry manufacturers is smaller than that of pig iron and steel castings, and its compressive strength is relatively high during actual operation. Therefore, the aluminum alloy castings are adopted under the standard of accepting the same load, which can reasonably alleviate the component of reasonable layout. Therefore In the aerospace industry and transmission equipment and transportation machinery and equipment to do, aluminum alloy profile foundry casting process to obtain widespread application.

Due to the large vaporization heat of solidification when casting aluminum castings by aluminum casting manufacturers, under the same standard as its component in actual operation, the solidification process of lithium bromide solution is much longer than that of steel castings and pig iron, with good liquidity, which is beneficial to casting thick-walled castings and disorderly castings with reasonable layout.

In the application industry of aluminum castings, the automobile manufacturing industry occupies a very large part, especially now the automobile manufacturing industry pays special attention to the characteristics of lightness, so the aluminum castings of aluminum casting manufacturers can be widely used in the automobile manufacturing industry. This is also because the relative density of aluminum castings is specifically lighter than that of iron castings and their steel castings, and the compressive strength of aluminum castings is greater throughout the application.

After casting by aluminum casting manufacturers, the net weight of aluminum casting itself becomes lighter. At a certain level, it can bear higher net weight. In the whole process of carrying out the design scheme, aluminum casting manufacturers must reasonably alleviate the net weight of their castings, so that aluminum casting can be widely used in industrial production, conveying machinery and transmission equipment.

Key words:

Recommended News

What is the aluminum alloy casting process?

2022-08-31

How to Avoid Aluminum Alloy Casting Error

2022-08-22

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.