Aluminum Foundry Factory: Pouring Temperature and Advantages of Aluminum Casting

Release time:

2020-12-10

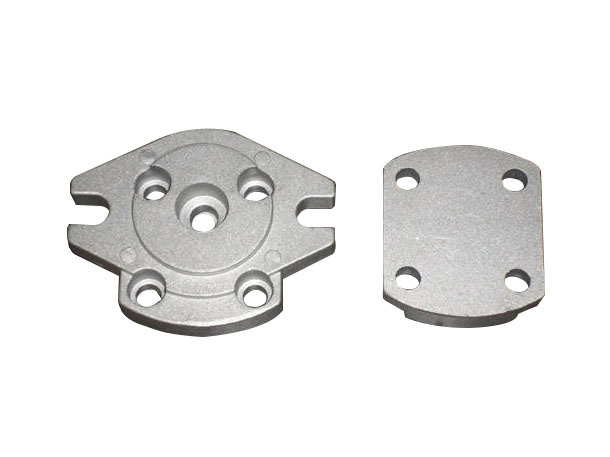

The aluminum foundry improves the overall design of the castings throughout the actual operation of casting aluminum castings. When constructing, avoid inclination angles and wall thicknesses to ensure that they are symmetrical and smooth. Aluminum castings take measures to expand the tolerance of the sand mold (core) to ensure that a part of each of its castings is also condensed or sorted to improve the design of the gating control system.

The aluminum foundry improves the overall design of the castings throughout the actual operation of casting aluminum castings. When constructing, avoid inclination angles and wall thicknesses to ensure that they are symmetrical and smooth. Aluminum castings take measures to expand the tolerance of the sand mold (core) to ensure that a part of each of its castings is also condensed or sorted to improve the design of the gating control system.

The casting temperature of aluminum casting must be appropriately reduced to a certain level, and the cooling time of the mold must be controlled during use. The thermal calibration method is used when the casting is deformed. The heat treatment process temperature is appropriately controlled to reduce the heat treatment cooling rate.

The following are aluminum casting manufacturers to introduce the application advantages of aluminum castings:

1,Complex parts can be produced, in particular rough inner walls (e. g. radiators).

2、Wide adaptability, can be forged industrial production of common metal composite materials.

3,The raw materials used by aluminum foundry manufacturers come from high-quality, low-priced scrap steel.

4,The appearance and specifications of the castings are very close to the parts, reducing the amount of drilling, which is a production process without drilling.

Therefore, aluminum alloy castings manufactured by aluminum foundry manufacturers are widely used in the aerospace industry and the manufacture of transmission equipment and transportation machinery. At the same time because it has excellent surface gloss and excellent corrosion resistance in air and water. Therefore, it is also widely used in the manufacture of civil containers.

Pure aluminum has excellent corrosion resistance in oxide substances, so aluminum castings made by aluminum foundries also have some major uses in the chemical industry. Pure aluminum and aluminum alloys have excellent heat transfer performance, so they are used for heat exchange equipment in the production of chemical plants, such as parts with excellent heat transfer performance on designated equipment. The cylinder head and piston rod of the gas turbine are aluminum castings made by aluminum casting manufacturers.

Key words:

Previous Page

Recommended News

What is the aluminum alloy casting process?

2022-08-31

How to Avoid Aluminum Alloy Casting Error

2022-08-22

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.