Die casting manufacturers: what is die casting

Release time:

2020-12-14

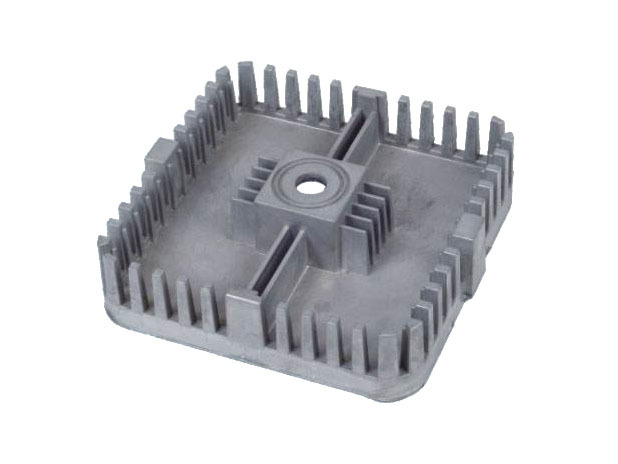

Die casting is a metal casting process commonly used by die casting manufacturers, which is characterized by the use of the cavity of the mold to apply high pressure to the molten metal. The mold is usually made of a high-strength alloy. This process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin and lead-tin alloys and their alloys. Depending on the type of die casting, die casting manufacturers need to use a cold chamber die casting machine or a hot chamber die casting machine.

Die casting is a die casting manufacturerCommonly usedA metal casting process is characterized by applying a high pressure to a molten metal using a cavity of a mold. The mold is usually made of a high-strength alloy. This process is somewhat similar to injection molding. Most die castings are iron-free, such as zinc, copper, aluminum, magnesium, lead, tin and lead-tin alloys and their alloys. According to the type of die casting, die casting manufacturers needUseCold chamber die casting machine or hot chamber die casting machine.

Die casting manufacturersUsed in die castingCost of casting equipment and moldsCompareHigh, so the die-casting process is usually only used for mass production of a large number of products. The manufacture of die-cast parts is relatively easy, usually only four main steps are required, and the increase in individual costs is very low. Die casting is particularly suitable for the manufacture of a large number of small and medium-sized castings, so die casting is used in various casting processes.CompareA broad one. Compared with other casting technologies, the die-casting surface is smoother and the dimensional consistency is higher.

On the basis of the traditional die casting process, die casting manufacturersCreationSeveral improved processes, including a non-porous die-casting process, which reduces casting defects and eliminates blowholes, were proposed. It is mainly used for zinc processing, which can reduce waste and increase the output of direct injection process. There are also new die-casting processes, such as precision die-casting technology and semi-solid die-casting invented by General Dynamics.

Die casting manufacturersusedThe traditional die casting process mainly includes four steps, otherwise known as high pressure die casting. These four steps include mold preparation, filling, injection and shaking, which are also the basis of various improved die casting processes. In the die casting manufacturersofDuring preparation, lubricant needs to be injected into the mold cavity.In addition to helping control the temperature of the mold, lubricants can also help demolding castings. Then, the die-casting manufacturer can close the mold and inject the molten metal into the mold under high pressure. After filling the molten metal, the pressure will be maintained until the casting solidifies. Then the putter will push outdie-cast goodCastings. Since there may be multiple cavities in the mold, die casting manufacturers may produce multiple castings during each casting process.

Key words:

Recommended News

What is the aluminum alloy casting process?

2022-08-31

How to Avoid Aluminum Alloy Casting Error

2022-08-22

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.