Die casting manufacturers: what is the die casting process

Release time:

2020-12-21

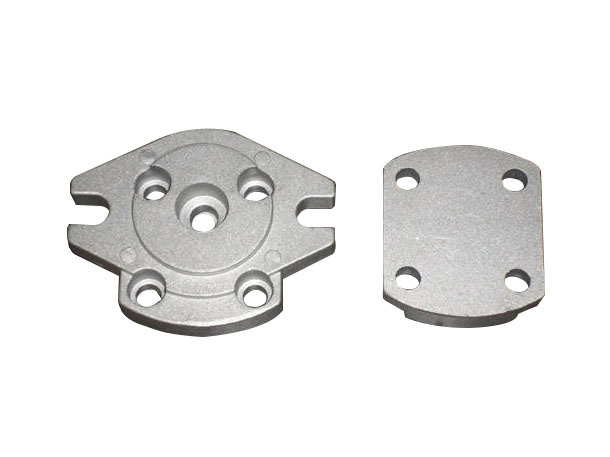

The traditional die casting process mainly includes four steps, or called high pressure die casting. These four steps include mold preparation, filling, injection and sand drop, which is also the basis of various improved die casting processes. In the process of preparing the die casting, the lubricant needs to be injected into the mold cavity. In addition to helping control the temperature of the mold, lubricants can also help demolding castings. Then, the mold can be closed, and then the molten metal is injected into the mold under high pressure.

The traditional die casting process mainly includes four steps, or called high pressure die casting. These four steps include mold preparation, filling, injection and sand drop, which is also the basis of various improved die casting processes. In the process of preparing the die casting, the lubricant needs to be injected into the mold cavity. In addition to helping control the temperature of the mold, lubricants can also help demolding castings. Then, the mold can be closed, and then the molten metal is injected into the mold under high pressure.

The pressure range for die casting by die casting manufacturers is approximately10 to 175MPa. After filling the molten metal, the pressure will be maintained until the casting solidifies. Then the pusher will push out all the castings. Since there may be multiple cavities in the mold, multiple castings may be produced during each casting process. The sand drop process requires the separation of residues, including mold openings, runners, gates, and fly edges. Die casting manufacturers usually through the use of special trimming die extrusion castings to complete this process. Other methods of dropping sand include sawing and sanding. If the gate is fragile, you can directly hit the casting, which can save manpower. The excess open die can be reused after melting. The usual yield is about 67%.

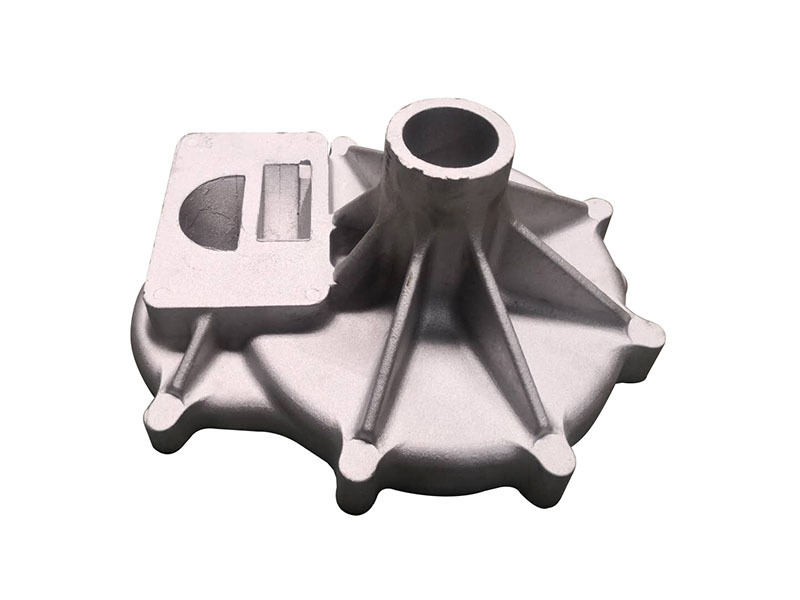

The high-pressure injection of die-casting manufacturers makes the mold fill very fast, so the molten metal can fill the entire mold before any part solidifies. In this way, even thin-walled parts that are difficult to fill can avoid surface discontinuities. However, this may also lead to air entrapment, as it is difficult for air to escape when filling the mold quickly. This problem can be reduced by placing an exhaust port on the parting line, but even a very precise process will leave a hole in the center of the casting. Most of the die-casting can be completed by secondary processing to complete some structures that cannot be completed by casting, such as drilling and polishing.

Defects can be checked after sand drop. Common defects include stagnation (unsatisfactory pouring). These defects may be caused by insufficient temperature of the mold or molten metal used by the die-casting manufacturer, mixing of metal with impurities, too few exhaust holes, and too much lubricant. Other defects include porosity, shrinkage, hot cracks and flow marks. Flow marks are marks left on the surface of the casting due to gate defects, sharp corners, or excessive lubricant.

Key words:

Recommended News

What is the aluminum alloy casting process?

2022-08-31

How to Avoid Aluminum Alloy Casting Error

2022-08-22

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.