Gravity casting

Key words:

Classification:

Product Description

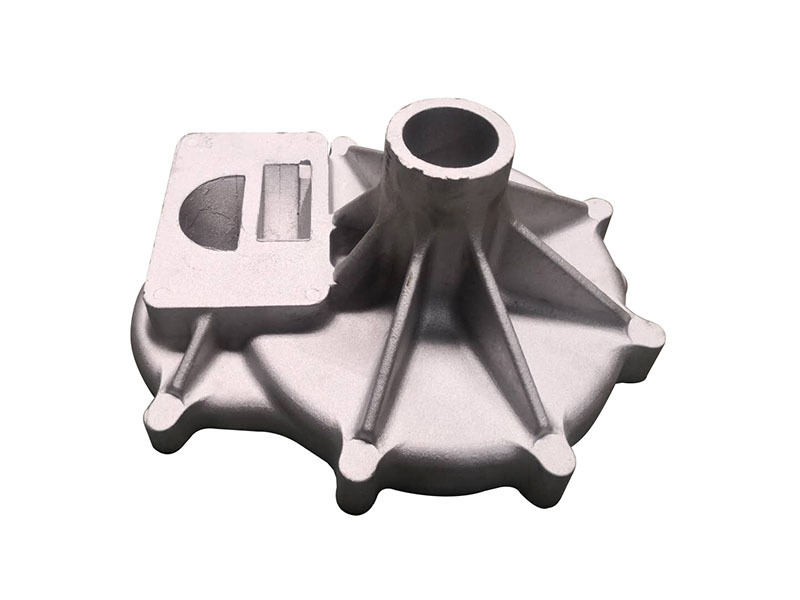

Gravity casting is a popular manufacturing process used by aluminum casting manufacturers to create high-quality aluminum parts. In this process, molten aluminum is poured into a mold cavity that is open to the atmosphere. Gravity is used to fill the mold cavity with the molten metal, creating a smooth surface finish and accurate dimensions. This method is ideal for producing complex shapes and thin-walled parts. Gravity casting is a cost-effective and efficient way to produce aluminum parts with minimal post-processing required. The end result is a durable and reliable product that meets the highest industry standards.

Related Products

Product inquiry

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.