Gravity Casting

Key words:

Classification:

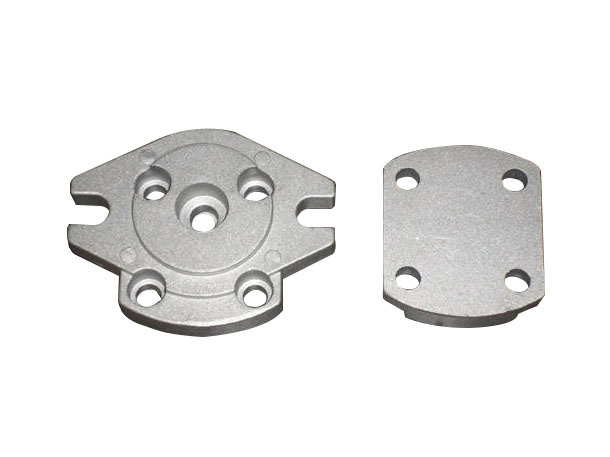

Product Description

Throughout the application process, aluminum castings have unparalleled advantages over other castings. The advantage is that in the new energy of automobiles, its cast aluminum alloy castings have been widely used in the production of the automobile industry.FoundryThe relative density of aluminum castings is smaller, but the specific strength of pig iron and cast steel is higher. Therefore, the use of aluminum alloy castings under the same load standard can reduce the weight of reasonable layout. Therefore,FoundryAluminum alloy castings have been widely used in the aerospace industry and the manufacture of transmission equipment and transportation machinery.

Aluminum castings inFoundryThe whole operation process has excellent casting effect. Their products have low melting points, so they can be widely used in metal materials and their working pressure casting methods to improve the internal quality of castings, and may also limit accuracy, surface smoothness and production output power.

Aluminum castings have greater heat of solidification and vaporization. Under the same standard, the solidification process of lithium bromide solution will continue to be much longer than that of steel castings and pig iron, and it has good fluidity, which is beneficial to aluminum casting manufacturers to cast thick walls and reasonable layout.

FoundryAfter pouring the high-temperature metal material liquid in the aluminum casting into the mold, the mold of the product will be filled with a lot of steam. The steam must be discharged from the mold immediately and successfully, and the molding sand can pass the steam. This property is called breathability. Otherwise, disadvantages such as vent holes and insufficient pouring may result. The air permeability of the mold is affected by the sand grain size distribution, clay composition, moisture composition and sand grain density.

FoundryThe ability of aluminum castings to resist external damage is called compressive strength. The molding sand must have a high enough compressive strength so that it will not collapse during the entire process of molding design, transportation and assembly, and will not damage the surface of the mold during the casting process.FoundryThe compressive strength of the molding sand used cannot be too high, otherwise the casting will cause defects due to reduced air permeability and tolerances.

Related Products

Product inquiry

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.