Low pressure casting

Key words:

Classification:

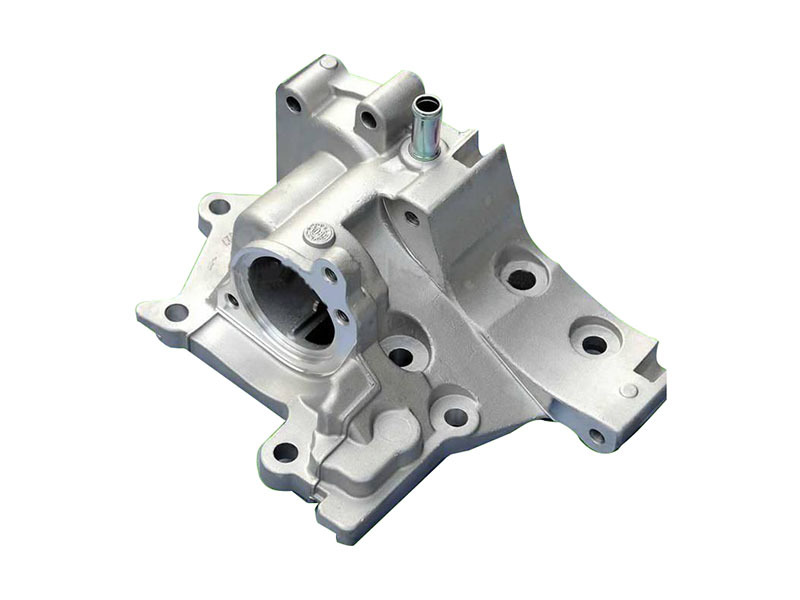

Product Description

Low pressure casting is usually used in the processing of many aluminum parts, and it is also very common in our lives. However, if the surface treatment is not effective during processing, it will also have a greater impact on product quality. Therefore, when we choose this kind of low-pressure casting, there are many aspects that must be paid attention. What should we pay attention to? Let'sTogetherCome on.Understand it.

Everyone knows.Surface treatment technology of low pressure casting parts?

The coating process can usually be divided into: spray coating, powder coating and electrophoresis. After the surface treatment of the workpiece, according to the appearance and corrosion resistance requirements of different workpieces, select the appropriate spraying process and equipment, and pay attention to control the leveling, drying, cooling and other processes, otherwise it will have adverse effects In terms of product quality. Usually, the spraying process can achieve better appearance quality. Spray coatings have good gloss, color and weather resistance, and are usually used in applications with high requirements for appearance, such as automotive exterior coatings and motorcycle fuel tanks.

As we all know, the processing system of low-pressure casting will affect the entire operation process, so what factors will affect low-pressure casting?

Reasonable low-pressure die design can dredge the feed channel in the forging process, and produce a good and fast sequential condensation effect, realize the condensation from the far end to the riser, prevent the appearance of forging defects, and improve the output power. Generally, the preheating temperature of the mold is suitable for reaching400-450°C. If the temperature of the low-pressure casting mold is too low or too high, the reasonable temperature field of the mold will be damaged, and the casting will be difficult to form or the pass rate will be reduced. The coating on the surface of the mold has the ability to resist thermal shock. The type, size and thickness of the spray coating on the surface of the mold will directly affect the function of the casting.

In the production of low-pressure castings, the quality of castings must be controlled and checked. We must formulate rules and technical conditions to control and inspect each specific product from raw materials, auxiliary materials to process compliance. Each process is strictly controlled and checked in accordance with the rules and technical conditions of the process.

Related Products

Product inquiry

Sales Hotline:+86-18331916658

Sales Hotline:+86-17732979583

Fax:0086-319-5672177

E-mail:pengyuzhuzao@163.com

Address: Dongding Village, Sujiazhuang Town, Ningjin County, Xingtai City, Hebei Province

View mobile phone official website

Copyright©2022 Ningjin Pengyu Auto Parts Co., Ltd.